Advantage

A century of Swedish craftsmanship

Centennial Process from Sweden, Origin of Powder High Speed Steel-Sö derfors Steel AB Steel Plant

Swedish Soderfors Steel AB is one of the best iron and steel enterprises in the world today. It has more than 300 years of iron and steel production experience, and has continuously developed and innovated. So far, it has accumulated profound experience and technology in the production of powder high-speed steel. One of the world's high-end powder steel mills.

Swedish Soderfors Steel AB is one of the few third-generation powder steel providers in the world today, and its predecessor is the birthplace of the third-generation powder steel production line AST. The three earliest production lines of three generations of powder high-speed steel in the world, the other two of which belong to Bohler (Bailu) and Carpenter (Carpenter), are all built with reference to the production line of Soderfors Steel AB. Therefore, the powder high-speed steel supplied by Soderfors Steel AB and the highest-end powder high-speed steel (Bohler, Assab) in the current market are maintained at the same level in terms of quality and heat treatment process.

Sino-Swiss Metals has long established a strategic partnership with Soderfors Steel AB and has become its exclusive general agent in Greater China. Sino-Swiss will work with Soderfors Steel AB to provide customers with the best quality products and related materials terminal services, hand in hand to move forward and create a better future!

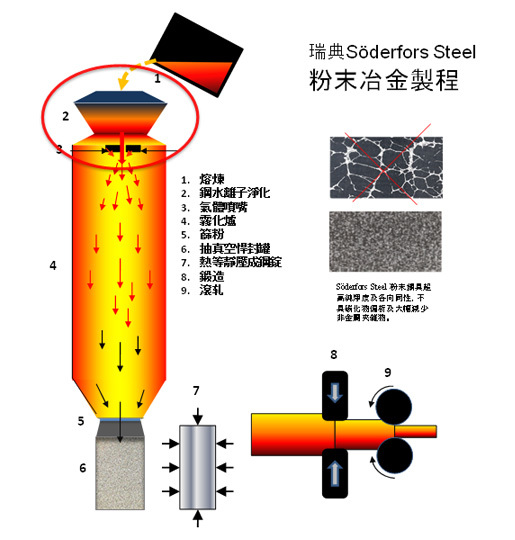

Powder Metallurgy Process

1. Smelting

2. Purification of molten steel

The molten steel is purified in the middle ladle under the protection of inert gas, so that the water can obtain ultra-high purity, greatly reduce the content of non-metallic inclusions in the steel, so that the steel can obtain high strength, toughness and good spin rotation.

3. Atomized ultra-fine steel powder

Using high purity nitrogen to atomize purified molten steel into ultrafine steel powder

4. Powder filling

The atomized fine steel powder is put into a low carbon steel tank after sieving, and then welded and sealed after vacuuming.

5. Hot Isostatic Pressing (HIP)

Using a high-power heater, the canned steel powder is simultaneously heated and pressurized in a high-pressure container for hot isostatic pressing to make steel ingots, which are then segmented and hot-rolled into powder steel.

Quick Navigation

Add.: Huangcaolang Second Industrial Zone, Dalang Town, Dongguan City, Guangdong Province, China

Tel.: +86-769-8313 7751

Fax: +86-769 - 8313 6003

E-mail: dgzr@zhongrui-7.cn

Follow Us

Copyright©2024 Dongguan Zhongrui Metal Material Co., Ltd.