Processing Services

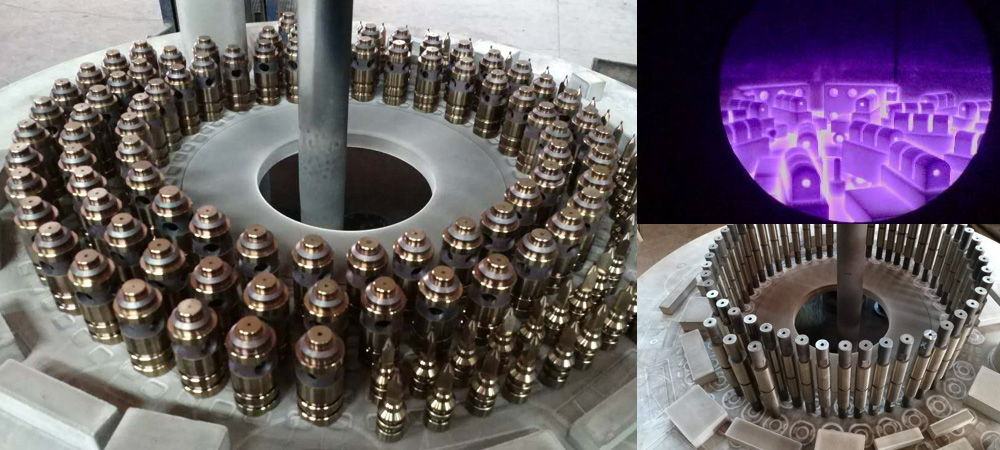

Ion Nitriding

Ion nitriding is different from traditional nitriding by chemical reaction, but the use of ionized nitrogen in a low vacuum environment for nitriding treatment has the following advantages and characteristics:

■ Non-toxic, odorless, environmentally friendly, will not produce chemical pollution

■ Seepage fast: compared with the traditional chemical nitriding time significantly shortened

■ The nitriding layer structure is easy to control and the brittleness is small: by controlling the content of nitrogen and carbon in the gas, the nitriding layer with different thickness and toughness can be obtained.

■ Small deformation of the workpiece: Ion nitriding can be heated and nitrided in vacuum at a relatively low temperature. Through controlling the heating and cooling rate, the temperature of the workpiece can be uniformly raised and lowered, and its deformation is smaller than that of traditional nitriding.

■ in vacuum, can get no oxidation of the processing surface, will not damage and the surface of the workpiece smooth

Sino-Swiss Ion Nitriding Process

Through ion nitriding, the alloy elements in the steel are combined with nitrogen to form fine dispersed nitrides, which can effectively improve the wear resistance, corrosion resistance, adhesion resistance and thermal fatigue resistance of the die steel surface. Effectively improve the service life of die steel.

Quick Navigation

Add.: Huangcaolang Second Industrial Zone, Dalang Town, Dongguan City, Guangdong Province, China

Tel.: +86-769-8313 7751

Fax: +86-769 - 8313 6003

E-mail: dgzr@zhongrui-7.cn

Follow Us

Copyright©2024 Dongguan Zhongrui Metal Material Co., Ltd.

Business License